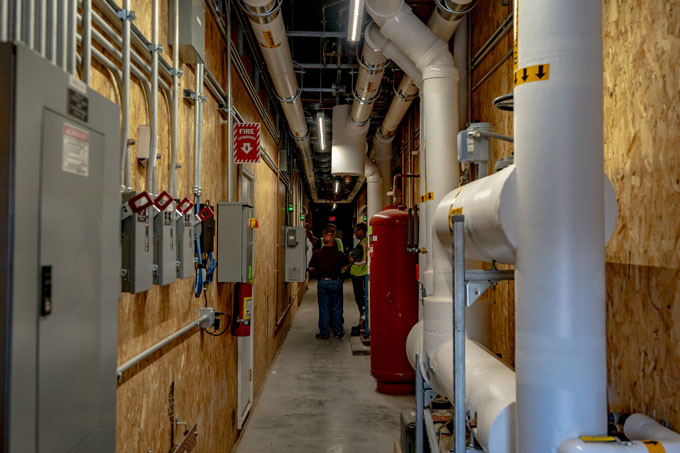

Precision wood drying that’s easy to use.

Nova Dry Kiln’s new Timber-Dry Management Control System utilizes state-of-the-art instrumentation that takes kiln drying into the 21st century and yet produces the brighter higher quality kiln dried product your customers have come to expect. By providing an easy-to-use and flexible operator interface, the kiln operator ultimately determines the optimum drying recipe for the lumber to be dried. This recipe is then sequentially executed automatically. The Timber-Dry Management Control System provides more information about the drying process, which leads to greater control over it, yielding increased quality and shorter drying times.

Features

- Preprogrammed drying procedures

- The ability to program custom drying schedules

- The capability to manipulate or suspend the drying schedule as it executes

- Maintains a record of process variables that can be exported to Microsoft Access or Excel such as

- wet bulb temperature

- dry bulb temperature

- exhaust setting

- Frequent wet bulb measurements

- Continuous dry bulb measurements

- Automatic control of floor temperature based on dew point to eliminate condensate

- Operator interface shows the drying sequence as it is executed in real time

- Multiple kiln operation is possible through one operator interface

Benefits

- Reduced drying time (up to 3 days per kiln charge vs. manual method.)

- Increased drying efficiency due to a faster response time and shorter drying cycles

- Reduced kiln operator interface time since the control system is doing all the work

- Drying history data that enables quality assurance and tracking.